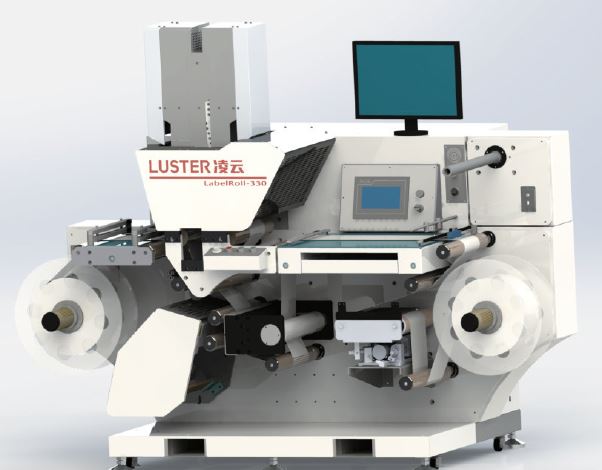

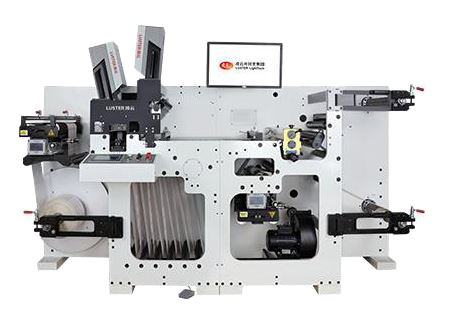

Individuell konfigurierbare Druckmaschinen

Nahezu alle angebotenen Maschinen sind betriebsbereit in unseren Räumlichkeiten installiert und können mit eigenen Daten und Bedruckstoffen ausgiebig getestet werden.

Erhalten Sie einen Überblick über

unser vielfältiges Sortiment

Bleiben Sie auf dem neusten Stand

Aktuelles

Haben Sie Fragen?